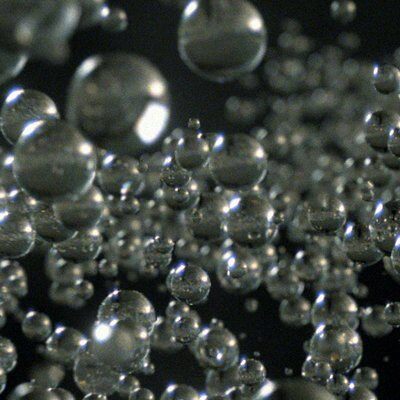

The general purpose K Series glass bubbles are the most versatile and economical 3M™ Glass Bubbles. Glass Bubbles K20 are engineered hollow glass spheres made from water-resistant and chemically-stable soda-lime borosilicate glass. Like all 3M glass bubbles, the K20 glass bubbles are water and oil resistant, providing better utility in underwater applications. Additionally, they are non-combustible and non-porous, so they do not absorb resin; and their low alkalinity makes this product compatible with most resins while providing a stable viscosity and a long shelf life.

3M glass bubbles are a superior alternative to many conventional fillers and additives such as silicas, calcium carbonate, talc, clay and other materials used in demanding applications. Our low-density spheres are used in a wide range of industries to reduce part weight, may lower costs and enhance product properties — making them more reliable and affordable than many alternatives such as cenospheres and perlite.

Sold by the Gallon.

1 review for Glass Bubbles