Description

SMALL STRUTS

STR14-A

Stronger than but compared to 1.275 Dia x .065 wall 6061T6 tubing.

- ULTIMATE = 18,012 PSI

- YIELD = 15,947 PSI

- SHEAR = 11,637 PSI

- AREA = .431 SQ IN

- CIRCUMFERENCE = 5.625

- WEIGHT = 0.517 #/FT

LARGE STRUTS

STR13-A

Stronger than but compared to 2.25 Dia x .065 wall 6061T6 tubing

- ULTIMATE = 23,268 PSI

- YIELD = 20,498 PSI

- SHEER = 14,958 PSI

- AREA = .554 SQ IN

- CIRCUMFERENCE = 7.125

- WEIGHT = 0.604 #/FT

HEAVY DUTY STRUTS

STR12-A

Stronger than but compared to 2.75 Dia x .090 wall 6061T6 tubing

- ULTIMATE = 36,582 PSI

- YIELD = 32,227 PSI

- SHEAR = 23,317 PSI

- AREA = .871 SQ IN

- CIRCUMFERENCE = 8.625

- WEIGHT = 1.05 #/FT

JURY STRUTS

STR-15

Stronger than but compared to .75 Dia x .065 wall 6061T6 tubing

- ULTIMATE = 7,938 PSI

- YIELD = 6,993 PSI

- SHEER = 5,103 PSI

- AREA = .189 SQ IN

- CIRCUMFERENCE = 2.531

- WEIGHT = 0.227 #/FT

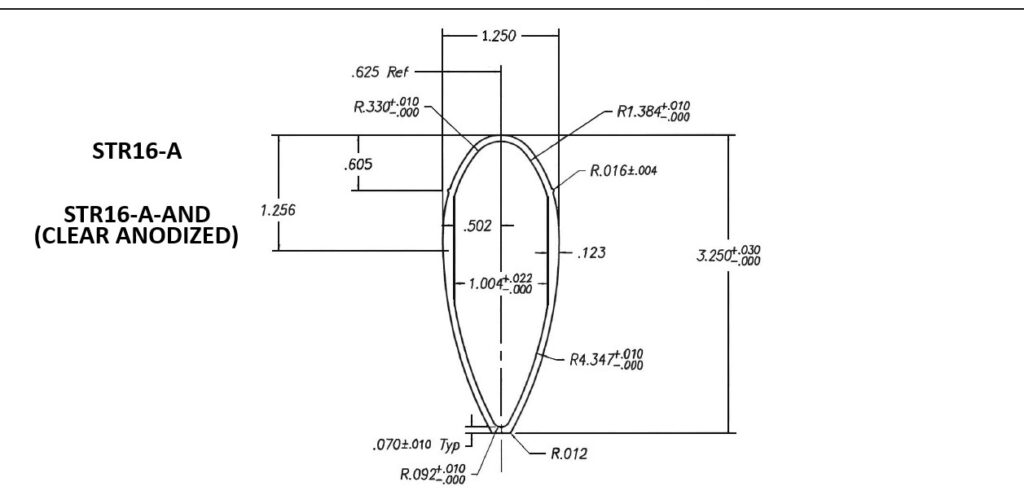

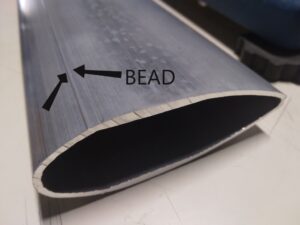

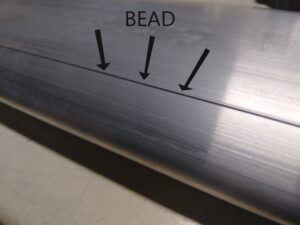

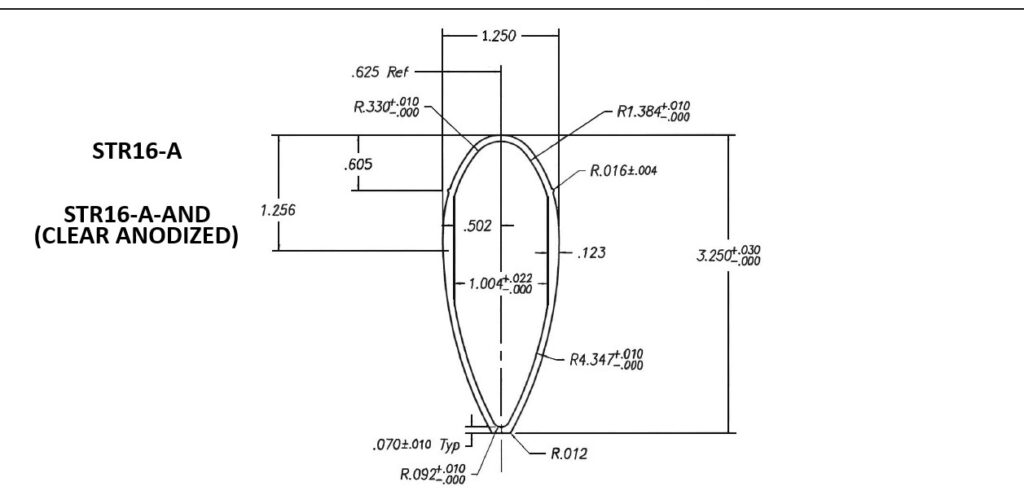

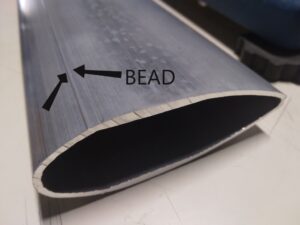

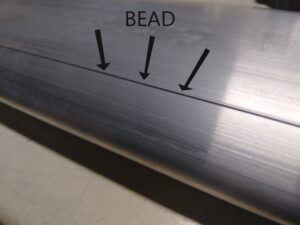

Our Streamline strut design has a trip line as part of the shape. The purpose is to reduce drag. The precise shape of the airfoil and location of the trip line was determined by engineers. It was developed using the wind tunnel at Embry Riddle University to prove out the shape in full size testing. It’s still the best streamline strut design of that size.

The term

“aero trip line” (more commonly, a “trip strip” or “tripping element”) refers to a small, intentionally placed aerodynamic feature used to force the airflow over a streamlined surface (like a wing or a strut) to become turbulent in a controlled manner.

Purpose and Function

The primary goal of a trip line on a streamlined strut is to reduce drag, not increase it, by promoting a specific type of airflow separation:

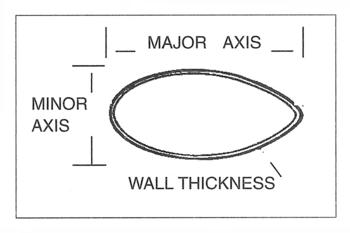

- Laminar vs. Turbulent Flow: Airflow over a smooth, streamlined shape naturally starts as laminar (smooth layers of air). While laminar flow has lower skin friction, it separates easily from the surface at a certain point. When it separates, it creates a large area of turbulent wake behind the object, which results in significant pressure drag.

- Forcing Transition: A trip line (often a small wire, a strip of tape, or a change in surface finish) disrupts the laminar flow and forces it to become turbulent earlier.

- Reduced Overall Drag: Although turbulent flow has higher skin friction than laminar flow, it has more energy and “sticks” to the streamlined shape (airfoil) much longer before separating. This results in a much smaller turbulent wake and significantly less pressure drag overall. The net effect is a substantial reduction in the total drag of the strut.

Application on Struts

Struts, like wings, are designed with an airfoil (teardrop) shape to minimize drag. Using streamlined struts can reduce drag by up to 90% compared to round tubes. The addition of a precisely placed trip line optimizes this effect, especially at specific flight speeds (Reynolds numbers).

Common Implementations

- Small Wire or Thread: A simple and effective method used in model aircraft and some ultralights involves gluing a thin piece of fishing or trimmer line to the surface at a specific chord position.

- Surface Modification: Roughening a narrow strip of the surface or applying a specific type of tape.

- Designed Fairings: Commercial fairings or custom-made carbon fiber/aluminum pieces are available that incorporate the optimal shape for maximum drag reduction.

2 reviews for 6061-T6 Aluminum Streamline Struts