Description

Decking the Doghouse

Installing a teak veneer deck is a practical and beautiful option for finishing a deck repair. Teak veneers can also be applied to decks, seats, cabin tops or hatches to improve the looks and value of any boat. To install teak on the doghouse, the owners of Zatara, a 1979 custom-built 50′ cutter, followed these steps in the WEST SYSTEM Fiberglass Boat Repair & Maintenance:

- Plan the location and pattern for the layout of the teak strips. Cut the strips to fit and mark them for reference as necessary.

- Prepare the bonding surfaces. Clean with a wax and silicone remover or solvent and abrade smooth surfaces with 50-grit sandpaper.

- Place the first set of teak strips in the desired location and mark the bonding area and reference location points on the strips and deck. Also, make sure you clearly mark the locations of each screw and washer on the planks of teak as these will be your only means of locating your screw holes when fastening the planks down into the epoxy bed. It is also helpful to number each plank in order to reference the location relative to neighboring planks.

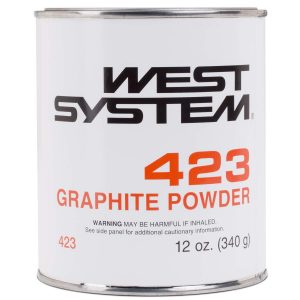

- Wet out the bonding surface of the first set of teak strips and the corresponding bonding area of the deck. Remember to solvent wipe the bonding surfaces of the teak 30 minutes before the wet-out. Apply a heavy layer of thickened WEST SYSTEM® 105/206 epoxy to the wet-out deck surface. Thicken the resin/hardener mixture to a mayonnaise consistency with 404 High-Density Filler. Then add enough 423 Graphite Powder to turn the mixture to an opaque black color. Apply enough thickened epoxy to bridge gaps between the strips and the deck and to squeeze up and fill the gap between the planks. Be sure to leave reference marks uncovered.

- Position the first set of strips on the deck. Use the reference marks as necessary.

- Clamp the strips in place with #10 sheet metal screws and large washers. Place the screws and washers between the strips, 8″ apart. Each row of screws will clamp the edges of two adjoining planks and act as spacers (below). Coat the screws and washers with a mold release (cooking non-stick spray) or place a small sheet of plastic under the washers to prevent bonding. Push adjoining strips tight against the screws before tightening the screws completely. Tighten the screws enough to hold the strips firmly and force some of the epoxy mixture to squeeze up between the strips.

- Bond the remaining strips in place, several at a time, following the same procedure.

- Remove the screws and washers within 24 hours. Fill the screw holes and remaining gaps between planks with epoxy/404/graphite mixture. A syringe loaded with the mixture will speed the process of filling the holes.

- Sand to level the surface and remove saw marks from the teak surface. Use a belt sander or disc sander with 50-grit sandpaper for the initial sanding. A commercial floor sander works well for large decks. Finish with 80-grit and then 120-grit sandpaper. The teak surface may be left natural or finished with marine-grade teak oil, marine varnish or WEST SYSTEM™ 105 Resin/207 Hardener and a high-quality two-part polyurethane varnish.