The traditional 4130 streamline is produced by a cold drawn process in short random lengths (typically ranging between 10 and 17 feet), whereas High Performance streamline is produced by a roll form process, in which round tubes are sent through a progressive series of rollers and dies. While the cold draw can produce streamline faster and in large quantities, this process produces a more consistent and repeatable shape. Roll forming is a consistent and gentle operation with fixed tooling. The dies used in the cold drawing process are not fixed and are redressed to produce different sizes, meaning less consistency from batch to batch. This process also has a greater variable in tolerance, so it’s not uncommon for traditional streamline tube to have a bow to them yielding a product that is not always very straight.

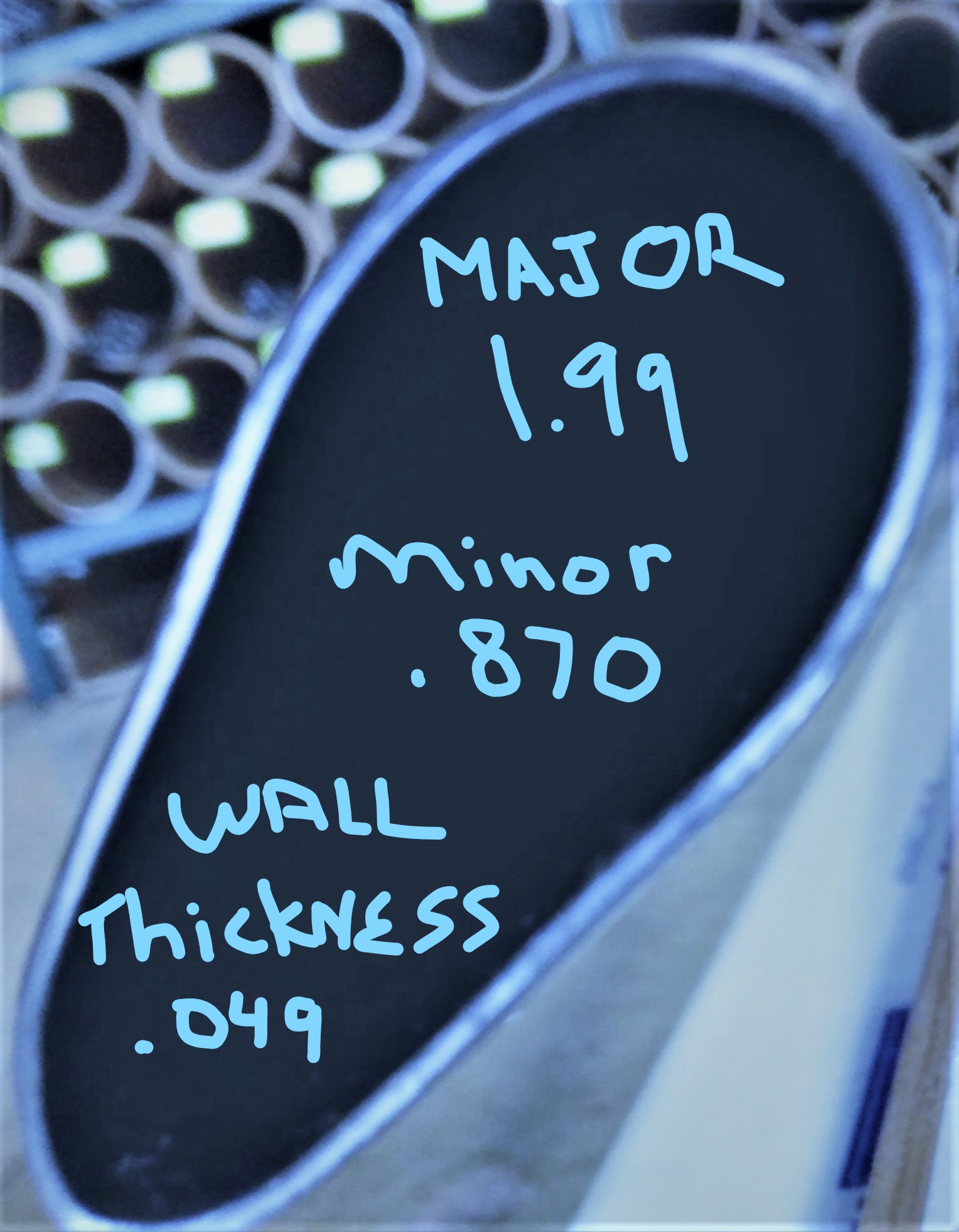

It is important to understand that these profiles DO NOT match exactly to the old “traditional” profiles of the past. The trailing edge (small radius on the minor dimension) has a larger radius.

Note: 1/8″ tolerance on cuts